Bendix AD-9 Air Drying Process

The information on this page describes how the Bendix AD-9 functions during normal operation. You should see our AD-9 troubleshooting information or download the Bendix AD-9 Service Data Sheet if you’re trying to diagnose a problem with your air dryer. We also sell new AD-9s as well as AD-9 service parts.

OVERVIEW

Every truck with air brakes has an air compressor on the engine. The air compressor keeps the air tanks full, so there is always air available to stop the truck. All air has a certain level of humidity which means that there is always water vapor in the atmosphere no matter if you’re in a dry or damp climate. Air is heated as it’s compressed, and it cools as it travels through the discharge line to the air tank. This cooling results in condensation creating pools of water in the bottom of the truck’s air tanks. You will also find oil from the compressor and any contaminants that made it through the compressors air filter in the the water.

Air dryers were created to minimize the amount of moisture and other contaminants that make it to the air tanks. The Bendix AD-9 air dryer alternates between two modes or “cycles” during use, the charge cycle and the purge cycle. Both cycles play an important part in keeping your air tanks as clean as possible.

AD-9 CHARGE CYCLE

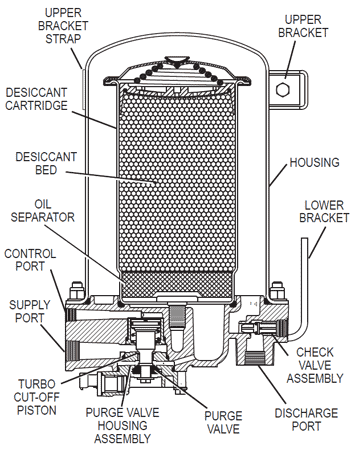

With an AD-9 air dryer installed, contaminants enter the supply port of the air dryer end cover. As the compressed air travels through the end cover assembly, its direction of flow changes several times causing contaminants to condense and drop to the bottom of the air dryer end cover.

The compressed air exits the end cover and flows into the desiccant cartridge where it flows through an oil separator that removes any water as well as oil and solid contaminants. The air then leaves the oil separator and enters the desiccant drying column. The moist air flowing through the column of desiccant becomes progressively drier as the water vapor absorbs into the desiccant material. The desiccant cartridge removes 95% of the water vapor from the pressurized air.

Most of the dry air exits the desiccant cartridge through a built-in single check valve and fills the purge volume

between the desiccant cartridge and outer shell. Some air exits the desiccant cartridge through the purge orifice near the check valve.

The dry air is then moved out of the purge volume through the single check valve and out the delivery port to the first (supply) reservoir of the air system. The air dryer stays in the charge cycle until the air brake system pressure reaches the governor cutout setting.

AD-9 PURGE CYCLE

The purge cycle of the air dryer begins when the governor causes the compressor to unload (stop compressing air). During compressor unload, the line connecting the governor unloader port to the AD-9 air dryer end cover control port is pressurized. The air pressure causes the air dryer purge valve to open. Contaminants in the end cover sump are expelled immediately when the purge valve opens. At the same time, the air that was traveling through the desiccant cartridge reverses direction and begins to flow to the open purge valve removing oil and solid contaminants collected by the oil separator.

The initial purge and desiccant cartridge decompression happens in just a few seconds and is evidenced by a burst of air at the AD-9 air dryer exhaust.

The flow of dry air through the desiccant cartridge drying bed reactivates the desiccant material by removing the water vapor it previously absorbed. It normally takes 15-30 seconds for the entire purge volume to flow through the desiccant drying bed.

The single check valve in the AD-9 end cover keeps air pressure in the brake system from blowing back into the air dryer during the purge cycle.

The purge valve will not close until air brake system pressure is reduced and the governor signals the compressor to begin compressing air again. That will start the next charge cycle.